Steel hollow section, known for their strength, versatility, and adaptability, serve as integral components in the construction and engineering industries. These specialized steel shapes, with their hollow structure, play a crucial role in modern architectural designs, infrastructure development, and various engineering applications. In this article, we delve into the characteristics, diverse types, and widespread applications of steel hollow sections.

Understanding Steel Hollow Sections

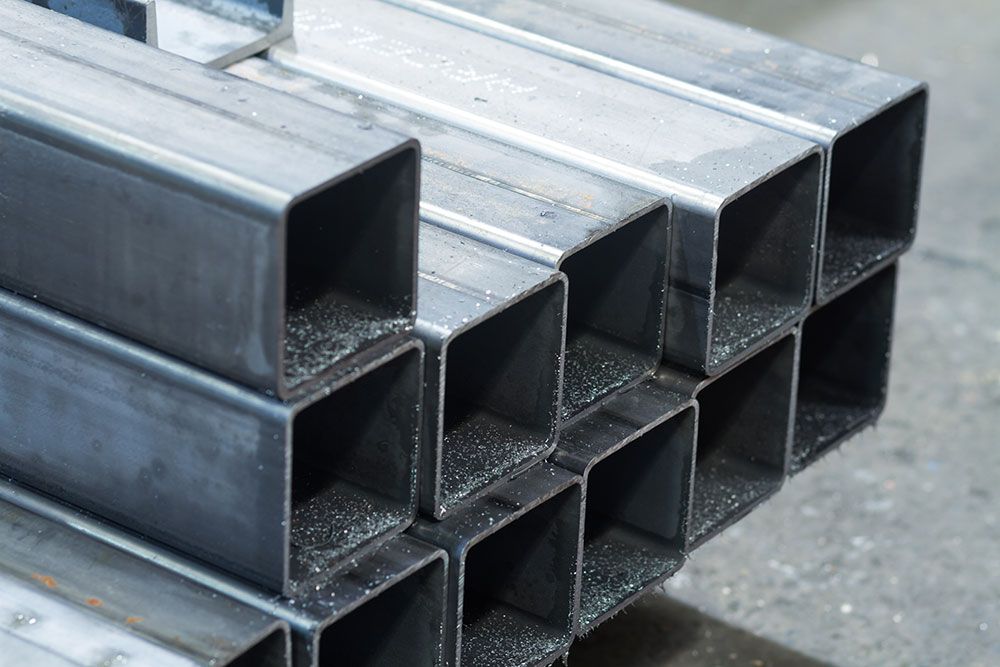

Steel hollow sections, also known as structural steel tubes or hollow structural sections (HSS), are steel profiles that feature a hollow, tubular cross-section. These sections are available in various shapes, including square, rectangular, circular, and other custom profiles. The unique geometry of hollow sections provides several advantages:

-

Strength and Load-Bearing Capabilities: Steel hollow sections are engineered to efficiently bear heavy loads while maintaining structural integrity. The hollow design distributes forces evenly, offering exceptional strength-to-weight ratios.

-

Flexibility in Design: Their versatility in shape and size enables engineers and architects to design structures with greater flexibility. This flexibility allows for innovative and aesthetically pleasing architectural designs.

Types of Steel Hollow Sections

-

Square Hollow Sections (SHS): These sections have a square cross-section, offering uniform strength in both directions. They are commonly used in construction for beams, columns, and other structural elements.

-

Rectangular Hollow Sections (RHS): RHS, with a rectangular cross-section, provides higher bending capabilities in one direction and is frequently used in building frames, trusses, and supports.

-

Circular Hollow Sections (CHS): With a circular profile, CHS offers uniform strength around its circumference, making them ideal for applications such as poles, pipelines, and mechanical applications.

Applications of Steel Hollow Sections

Steel hollow sections find extensive use across diverse industries due to their superior structural properties. Here are some key applications:

-

Construction and Architecture: Hollow sections are widely employed in the construction of buildings, bridges, and infrastructure. They form the backbone of structural elements, providing strength and stability to the overall framework.

-

Industrial Machinery and Equipment: These sections are crucial in the manufacturing of heavy machinery, conveyors, and material handling equipment due to their load-bearing capacity and structural reliability.

-

Transportation: Steel hollow sections are utilized in the fabrication of vehicle frames, trailers, and railway carriages due to their strength and durability.

-

Furniture and Interior Design: In modern interior design, steel hollow sections are used for creating stylish and sturdy furniture pieces, showcasing their aesthetic appeal and versatility.

-

Energy and Offshore Structures: Hollow sections play a vital role in the construction of offshore platforms, supporting structures for wind turbines, and other energy-related infrastructure due to their ability to withstand harsh environmental conditions.

Conclusion

Steel hollow sections stand as the backbone of modern engineering, offering exceptional strength, versatility, and a wide array of applications across various industries. Their adaptability in design and robust structural properties make them indispensable in construction, architecture, machinery, transportation, and many other fields. As engineering innovations continue to evolve, steel hollow sections will undoubtedly remain a fundamental component in shaping the infrastructural landscape, delivering robustness and stability to a wide range of applications.

For More Info:-